Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

Many shielding covers are in the same industry, and they are very depressed to see that other hardware manufacturers produce products with a high pass rate, but their own factories are very low. In addition, there will be a situation where the scrap rate is too high. When the scrap rate is high, it will not only increase the production cost, but also do not meet the concept of energy saving and environmental protection. Here, the editor will give you an analysis of several reasons that affect the quality of shielding cover products:

Several reasons affecting the quality of shielding cover products:

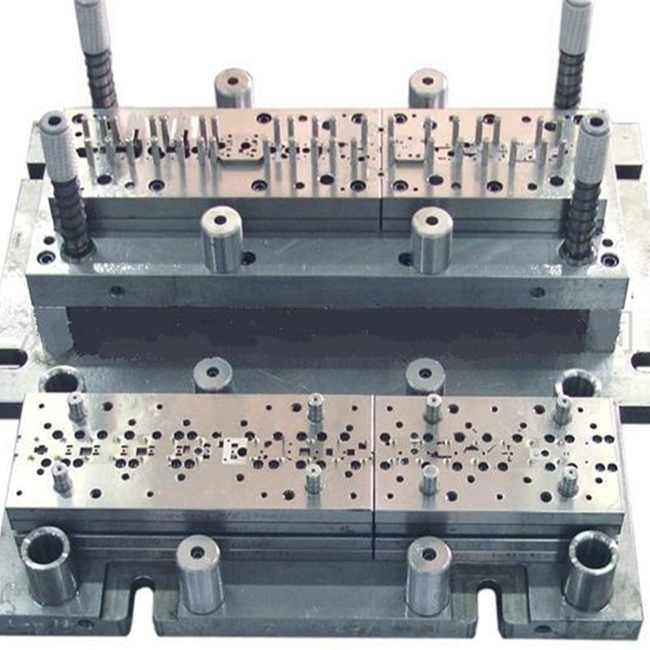

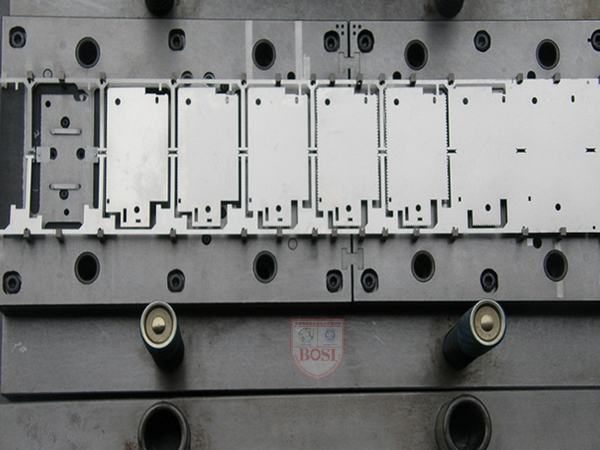

1. The problem of stamping die.

The most common reason for the poor quality of the shielding cover is the problem of the stamping die. The price of different mold factories for the same shielding cover is very different, which is mainly affected by the mold design ideas and mold materials. For stamping dies produced by unprofessional mold factories, although the appearance looks good and can be used normally, the production efficiency, stamping accuracy and service life are not comparable to those made by professional mold factories.

2. The problem of raw materials.

Nowadays, many shielding cover manufacturers like to credit the material suppliers. If the checkout is not timely, the quality control of the material will gradually become lax. Secondly, many customers of stamping factories are also constantly lowering their prices. Over time, stamping factories will also find ways to reduce production costs, and even use leftovers to produce stamping parts.

3. Production Problems.

Nowadays, it is more difficult to find stamping workers, so many stamping factories are constantly reducing their requirements when recruiting workers, which also leads to a corresponding reduction in the operation level of workers. Moreover, many metal stamping factories do not have a complete training system, which leads to workers without product quality awareness and operating punches in violation of regulations, resulting in product quality problems. On the other hand, the wages of stamping workers are low, the labor intensity is high, and the working environment is harsh, and the product quality will inevitably be affected. In the stamping plant, bumps and scratches on the product surface caused by the rough actions of workers can often be seen.

4.

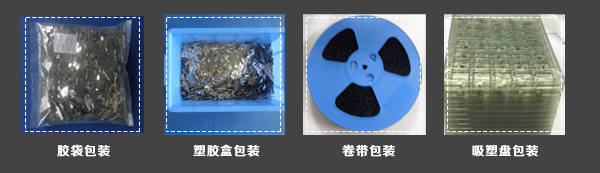

4. Shipping issues.

When the product is transported, it must be well packaged. Some enterprise products are directly guaranteed by simple woven bags when they leave the factory, which will inevitably cause product scratches and losses in the long-distance transportation of logistics. And our Dongguan Bosi packaging is very strict, and also according to the requirements of customers, there are tape packaging, plastic box packaging, roll bag packaging and blister packaging, which is a good protection product.

5. enterprise management issues.

The quality inspection department of a metal stamping enterprise plays a vital role in the entire enterprise, and the quality inspection department must be independent. The quality inspection departments of many enterprises are subordinate to other departments and cannot be independent, which has caused great trouble to the quality control of metal stamping parts.

The above is the Shenzhen shielding cover manufacturer: http://www.bosiwj.com/in-08.html

The editor lists several reasons that affect the quality of shielding cover products. Major shielding cover manufacturers can learn from them. In order to produce qualified shielding covers, metal stamping enterprises must have a sound management system. All departments of the company have complete rules and regulations. If you are interested in our company's products, you may wish to consult and communicate with us online.

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

How to correctly mount the manual soldering points of shielding components

Reasons for the high rejection rate of shields

How to select materials for automotive precision stamping parts?

Dongguan metal stamping die manufacturers: several skills that metal stamping die processing personnel need to master

Which company is more professional in producing mobile phone shield cover in Dongguan?

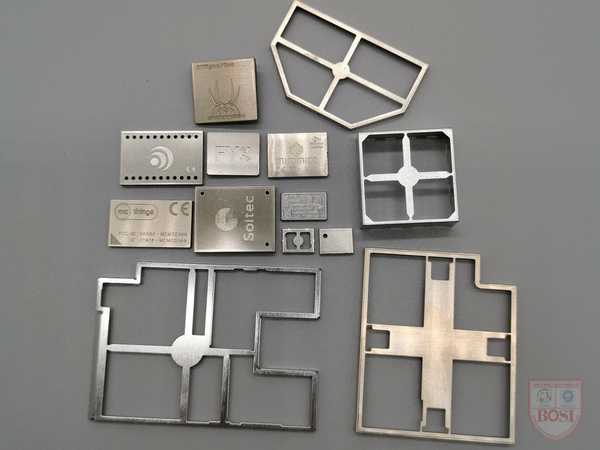

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

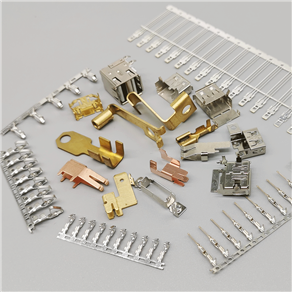

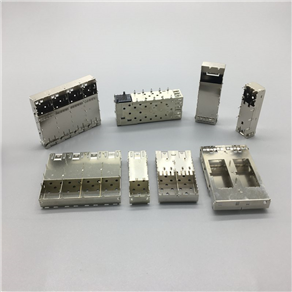

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

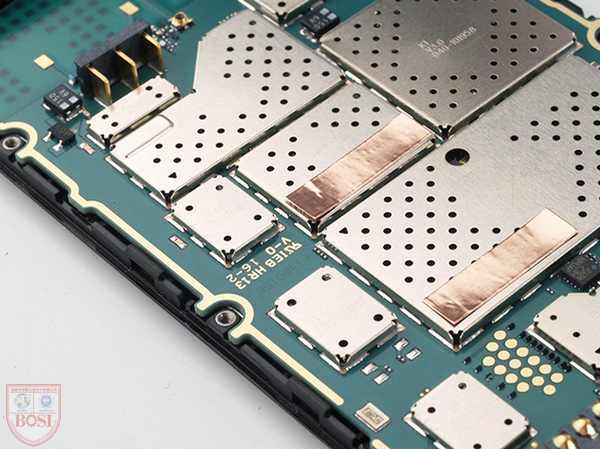

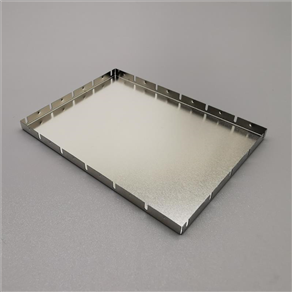

5g shielding case

easy to tin, automatic packaging without oxidation.

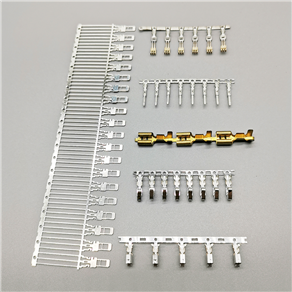

五金连接器

接线端子主要用于插座、开关、汽车等行业

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子