Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

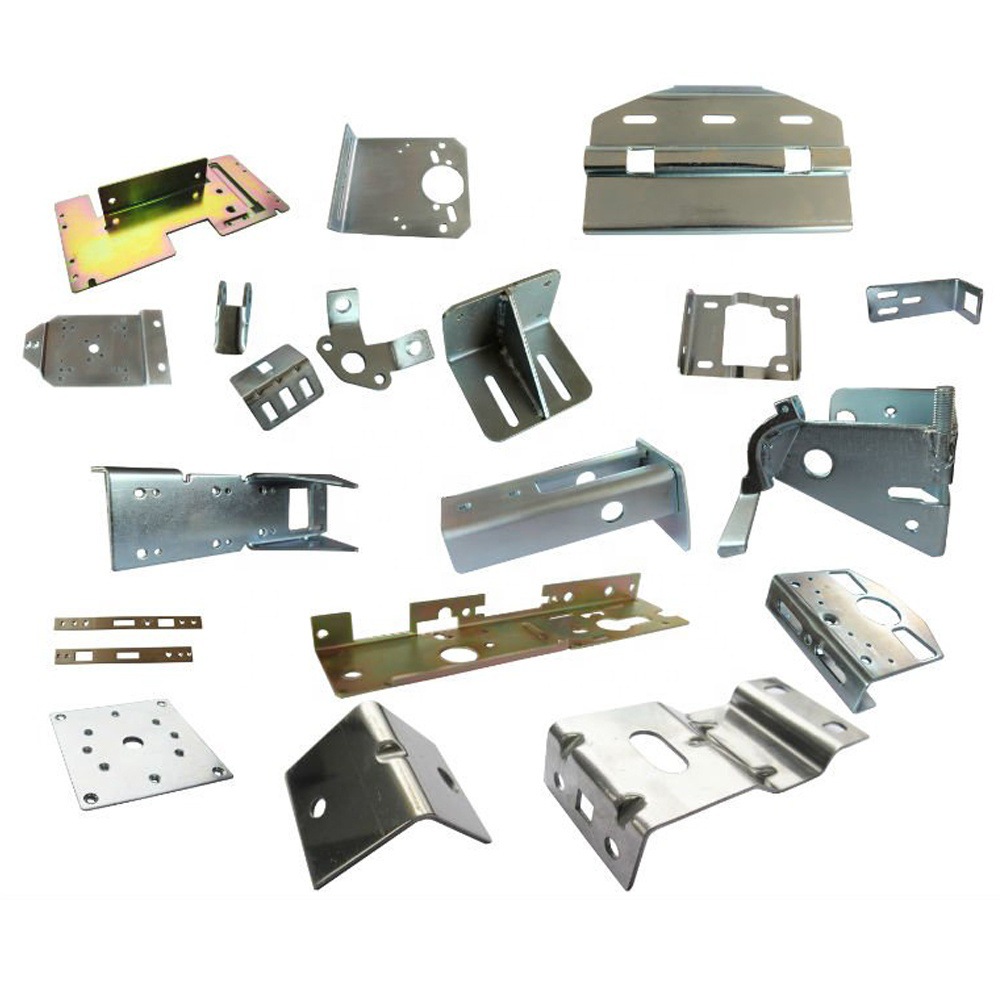

The domestic metal stamping industry is constantly catching up with the world's advanced level, and constantly narrowing the technological gap with developed countries, so the products of metal stamping parts are ubiquitous in daily life, so what should metal stamping manufacturers pay attention to when producing stamping parts to be able to To ensure the quality of the product, the following editors have sorted out a few points for your reference.

Attention points in the production of metal stamping parts:

1. Regularly check the die mounting base of the punch turntable and stamping parts to ensure the coaxial accuracy of the upper and lower turntables.

2. Metal stamping parts should be strictly inspected before installation and use, the dirt should be removed, and the guide sleeves and molds of drawing stamping parts should be carefully checked to see if they are well lubricated.

3. In order to ensure the service life of the tension and compression parts, the spring of the mold should be replaced regularly to prevent the fatigue damage of the spring from affecting the use of the tension and stamping parts.

4. When installing the mold, the stamping personnel should use soft metal to manufacture operating tools to prevent damage to the stamping parts when they are knocked and crushed during the installation process.

5. When the punch and die edges of stamping parts are worn, they should be stopped in time and sharpened in time. Otherwise, the wear degree of the die edges will be rapidly expanded, the die wear will be accelerated, and the quality of the stamping parts and the life of the die will be reduced.

6. According to the installation procedure of the die, install the convex and concave die on the turntable to ensure that the direction of the convex and concave drawing stamping parts is consistent, especially the stamping parts with direction requirements should be carefully installed to prevent wrong installation and reverse installation.

How to ensure the quality of metal stamping parts:

1. Chemical analysis, metallographic examination

Analyze the content of chemical elements in the material, determine the grain size level and uniformity of the material, evaluate the level of free cementite, banded structure and non-metallic inclusions in the material, and check the material for defects such as shrinkage and porosity.

2. Material inspection

The materials for stamping parts are mainly hot-rolled or cold-rolled (mainly cold-rolled) metal sheet and strip materials. The raw materials of metal stamping parts should have a quality certificate, which ensures that the materials meet the specified technical requirements. When there is no quality certificate or for other reasons, the metal stamping parts manufacturer can select raw materials for re-inspection as needed.

3. Formability test

Perform bending test and cupping test on the material, and measure the work hardening index n value and plastic strain ratio r value of the material. In addition, the test method for the formability of the steel plate can be carried out according to the provisions of the formability and test method of the thin steel plate.

4. Hardness testing

The hardness test of metal stamping parts adopts Rockwell hardness tester. Small, complex-shaped stampings can be used to test small planes that cannot be tested on ordinary benchtop Rockwell hardness testers.

5. Determination of other performance requirements

Determination of the electromagnetic properties of materials and the adhesion of coatings and coatings.

The above is about the main points of attention in the production of metal stamping parts introduced by the editor of Bosi Hardware: http://www.bosiwj.com/mp-11.html

And the relevant knowledge of how to ensure the quality of metal stamping parts, I hope it can help everyone. If you want to know more about this, please continue to pay attention to Bosi College

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

Germany imported equipment, Rapid proofing technology

CNC Micro Equipment - Metal Shrapnel Proofing

What are the technical requirements for the production of metal stamping and deep drawing parts? How to choose hardware deep drawing parts?

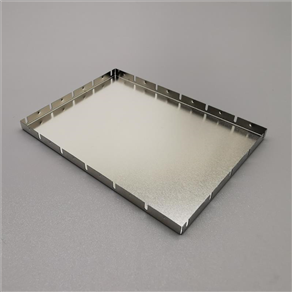

What material is generally used for the shielding cover?

How to correctly process precision metal stamping parts and precautions in the production process of stamping dies?

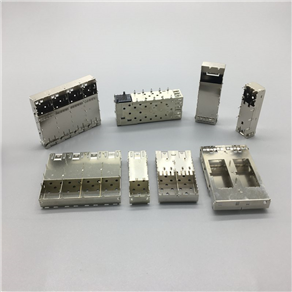

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

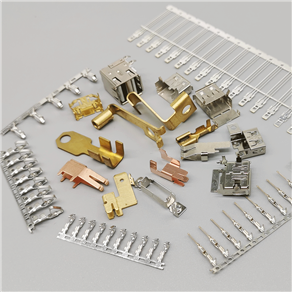

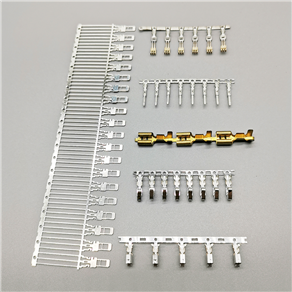

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

5g shielding case

easy to tin, automatic packaging without oxidation.

五金连接器

接线端子主要用于插座、开关、汽车等行业

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子