Dongguan BOSI Hardware Electronics Co., Ltd.

German craftsmanship, rapid proofing, non-standard customization, high accuracy

Fllowing BOSI

Official Account

Fllowing BOSI

Official Account

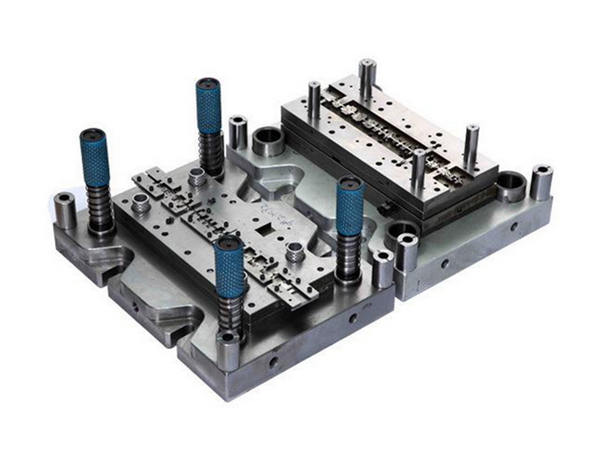

The production process of the die is the whole process of assembling the die parts into a die according to the technical requirements of the design and process regulations through casting, forging, cutting and special processing from the raw materials to the die parts required by the design drawings. Punching die is an indispensable die in stamping production. Punching die can be basically divided into three types: simple die, continuous die and compound die.

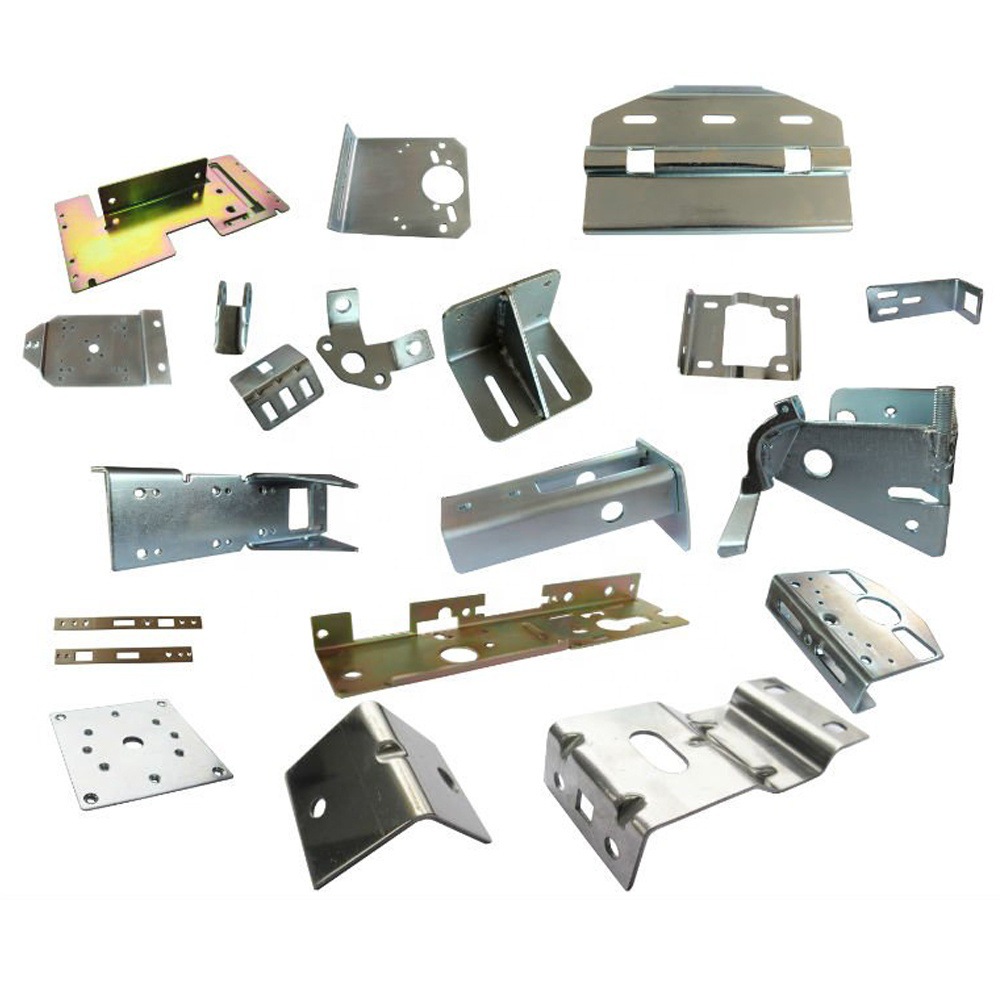

The important role of the die in the production of stamping parts:

Simple die

A simple die is a die that only completes one process in one stroke of the punch. That is, a simple die for blanking or punching. When working, the strip is fed along the two guide plates 9 on the die until it hits the positioning pin 10. When the punch is punched down, the punched parts (or scrap) enter the die hole, while the strip clamps the punch and moves back up with the punch. When the strip hits the stripper plate 8 (fixed on the die), it is pushed down, so that the strip continues to be fed between the guide plates. Repeat the above action to punch down the second part.

Continuous die

In one stroke of the punch, a die that simultaneously completes several stamping processes on different parts of the die is called a continuous die. When working, the ding pin 2 is aligned with the pre-punched positioning hole, the upper die moves downward, the punch 1 is blanked, and the punch 4 is punched. When the upper die returns, the stripper plate 6 pushes the scrap from the punch. At this time, the blank 7 is fed forward again, and the second punching is performed. This cycle is carried out, and each feeding distance is controlled by the stopper pin.

Compound die

In one stroke, a die that completes several stamping processes on the same part of the die at the same time is called a compound die. The biggest feature of the composite mold is that there is a convex and concave mold 1 in the mold. The outer circle of the punch and concave die is the cutting edge of the blanking punch die, and the inner hole becomes the deep drawing die. When the slider moves down with the punch and die, the strip is first blanked in the punch and die 1 and the blanking die 4. The blanking part is held up by the deep drawing punch 2 in the lower die, and when the slider continues to move downward, the die moves downward for deep drawing. The ejector 5 and the unloader 3 push the drawn part 9 out of the die during the return stroke of the slide. The compound die is suitable for stamping parts with large output and high precision.

The above is about the important role of the die in the production of stamping parts: http://www.bosiwj.com/mp-14.html

I hope it can help everyone and increase the knowledge of the role of punching die. If you need custom molds, please contact us.

Scan QR Code To Follow BOSI Official Account

Always know the latest free proofing benefits

Learn more about the latest news

Germany imported equipment, Rapid proofing technology

CNC Micro Equipment - Metal Shrapnel Proofing

What are the technical requirements for the production of metal stamping and deep drawing parts? How to choose hardware deep drawing parts?

What material is generally used for the shielding cover?

How to correctly process precision metal stamping parts and precautions in the production process of stamping dies?

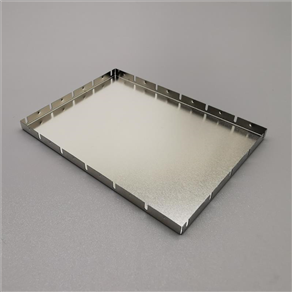

Quick proofing of shielding cover

Accuracy 0.01mm, flatness 0.02mm, imported German CNC micro-proofing machine, one day proofing saves mold opening

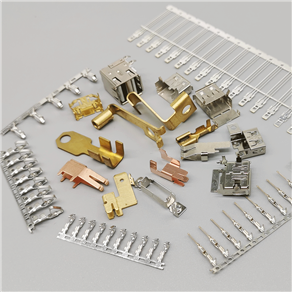

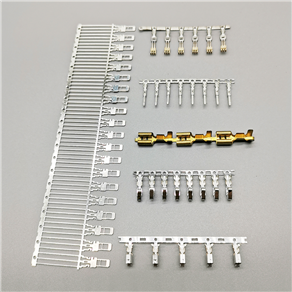

Precision Hardware Connectors (Terminals)

Small size, accuracy up to ±0.02mm, minimum processing thickness of 0.08mm, maximum processing thickness of 0.8mm, MINI-……

5g shielding case

easy to tin, automatic packaging without oxidation.

五金连接器

接线端子主要用于插座、开关、汽车等行业

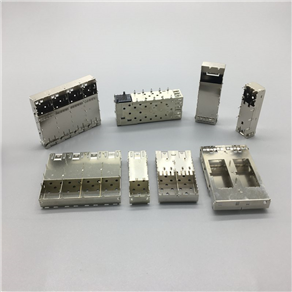

Precision Shield Case

SFP光纤连接器

单口及多口光纤连接器/端子